Akkuyu Nuclear Power Station

Akkuyu Nuclear Power Plant is planned to be the first nuclear power plant of Turkey.

General Information:

Project Name: Akkuyu Nuclear Power Plant

Customer: Republic of Turkey Ministry of Energy and Natural Resources

Employer: AKKUYU NUCLEAR A.Ş.

Project Participants:

Rosatom State Enterprise

Atomenergoproekt A.Ş.

Atomstroyexport Inc.

Concern Rosenergoatom A.Ş.

Kurchatov Institute National Research Center

Worley Parsons Energy Services LLC

Rusatom Energo International Inc.

OKB GIDROPRESS A.Ş.

Main contractor: TİTAN-2 & IC İÇTAŞ İNŞAAT ANONİM ŞİRKETİ

Reactor Type: VVER-1200

Power Capacity: 4800 MW

Project Model: Build – Operate – Own

Annual Production: 35 billion kWh

Project Cost: 20 Billion USD (approximately)

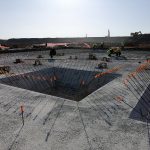

The reinforced concrete backfilling of the reactor’s standby control room building was casted by YÜCE YAPI up to the foundation bottom level. The building occupies an area of 2.940 m2 with a width of 18 m and a length of 35 m. The concrete was casted in layers to prevent any hydration and shrinkage cracks. 2.000 m3 concrete was casted.

The foundation of Liebherr 1000 EC-H40 tower crane was constructed by YÜCE YAPI. The DOKA FRAMAX was used for the form of the foundation.

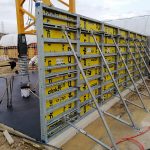

The mock-up castings for the self-compacting concrete mixture were carried out by YÜCE YAPI. For this purpose, the full scaled models of some parts of the reactor control building and reactor support buildings were prepared. DOKA FRAMAX formwork was used for this work. Following the placement of the steel embedded elements and rebar installation, thermocouplers were installed inside the formwork to continuously measure the temperature.

The placement of the concrete was monitored using self-compacting concrete and its propagation velocity was measured. After the concrete casting, the cooling duration of the concrete was monitored by performing temperature measurements of the test model every 8 hours during a period of 7 days. The duration of cracking and sizes of cracks were monitored by changing the curing method and curing time intervals of the concrete.