Marmaray

150 years dream came true by Marmaray Project opened on 29th October 2013 on the 90th anniversary of proclamation of the Republic of Turkey.

The project was implemented by a joint venture of TAISEI-GAMA-NUROL, with total length of line about 13,6 km.

It is a rail tunnel Project comprises an 1,4 km length immersed tube tunnel under the Bosphorus strait connecting Europe and Asia continents.

The most advanced tunneling techniques were used for construction of the tunnel: the approximately 1.4 km undersea tunnel was constructed by the immersed tunnel method, and the on-land tunnel was constructed by a combination of the shield tunnel method (constructed by TBM), NATM (New Austrian Tunneling Method), and cut and cover method.

The deepest part of immersed tube tunnel is 60 m below the sea surface, the world’s deepest. Immersed tube tunnels and the land tunnel is directly connected to each other under the sea, first time in the world. This is required great accuracy and safety to accomplish and deal with the challenges such as complex and rapid tidal currents in the Bosphorus Strait.

Project Summary:

Project Name: Marmaray BC-1 Contract

Client: General Directorate of Railways, Ports and Airports Construction (DLH), Turkish Ministry of Transport

Contractor: Taisei, Gama, Nurol JV

Total length of line: 13,6 km

Immersed Tube Tunnel Length: 1,4 km

Shield Tunnel Length: 9,8 km

Cut & Cover Length: 2,4 km

Passenger Capacity: 75.000 passenger/hour/each direction

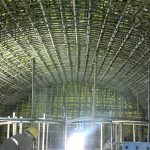

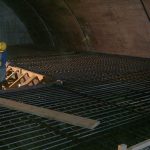

The largest arch lining within the scope of Marmaray Project has been applied by Yüce Yapı.

With an inner diameter of 14.73 m circular arch lining, the largest tunnel concrete lining of Marmaray Project was produced by Yüce Yapı.

Tunnel Length: 28.1 m

Casted Concrete: 1015 m³

Rebar Assembly: 114.5 tons

Steel Tunnel Formwork: 1223.5 m²

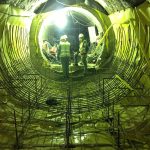

Arch linings of East Shaft at Sirkeci Passenger Platform Tunnels were produced by Yüce Yapı.

Tunnel length: 42 m

Concrete: 1645 m3

Rebar Assembly: 279 Tons

Wooden Butt Joint Formwork Fabrication: 410 m2

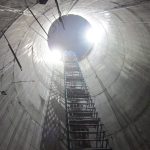

Concrete linings and inner structures of Escape Shafts and tunnels at Sirkeci Station were completed by Yüce Yapı.

Rebar: 252 tons

Steel climbing formwork for shaft lining: 942 m²

Tunnel Formwork: 20 climbing sequences (length of each set; 4.5 m- Tunnel diameter; 7.2m.)

Concrete: 2865 m3

INNER STRUCTURE:

Climbing formwork: 920.6 m2

Concrete: 184.1 m3

Rebar: 20.26 tons

Formwork: 214.1 m2

Concrete: 39 m3

Rebar: 4.59 tons

East and West Ventilation Shaft Transformer Buildings were constructed by Yüce Yapı.

Within this scope, 56.06 tons rebar, 1731 m2 formwork and 544 m3 concrete fabrication was carried out, and Yüce Yapı also completed all isolation, backfilling and finishing works of the project.

West Ventilation Slab was constructed by Yüce Yapı. The scaffolding built for construction of these slabs was a cantilevered scaffold to enable vehicle transition required for continuation of tunnel works. Within this scope, 23.22 tons rebar, 600.7 m2 formwork and 259.16 m3 concrete fabrication was accomplished.

Yüce Yapı accomplished construction of Sirkeci East and West Ventilation Shafts infrastructures, rainwater channels, waste water line and clean water line and integration of them to the main line, in addition, reorganization and landscape works of Sarayburnu storage site during the period handing over it to the employer.

Concrete works related to floodgates located at Sirkeci Station were performed by Yüce Yapı.

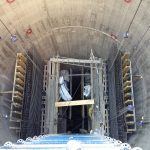

Having one of the largest invert cross-sections within the scope of Marmaray Project, PF and PFV Tunnel Invert concrete works under the East shaft were completed by Yüce Yapı.

Preparatory works for Sirkeci Station North Pedestrian Tunnel TBM entrance were performed by Yüce Yapı. To this end, the diaphragm wall was cut according to the cross-section of TBM by using a core, then it is demolished by an excavator, and finally a reaction wall was constructed for controlled entrance of TBM. Additionally, after completion of TBM excavation, tunnel invert and tunnel end wall were built.