Northern Marmara Motorway Project - Yavuz Sultan Selim Bridge

The contract had been signed by between KGM and ICA in 2013. The project runs along Ikıtelli to Camlik in Istanbul,Turkey. Yavuz Sultan Selim Suspension Bridge which connects Europe to Asia a part of motorway project. The total contract value of project is $2.5 billion. 3rd Bosphorus Bridge is one of the unique part of the project, the bridge towers (pylons) are the highest towers 322 meter in the world with a triangular inclined section and the bridge has the widest decks 59 meter with the 8 lanes of motorway and 2 lanes of railway. The contract has covered engineering, procurement and construction.

Project Summary:

Project Name: Northern Marmara Motorway

Client: Republic of Turkey Ministry of Transportation General Directorate Highways – KGM

Employer: IC Ictas – Astaldi Consortium

Bridge Contractor: Hyundai & SK Engineering Joint Venture

Motorway length: 95 km

Bridge Span: 1408 m

Contract value: $ 2.5 billion

Start of the work: May, 2013

End of the work: Aug, 2016

Being the third bridge project spanning the Bosphorus Strait – İstanbul, Yavuz Sultan Selim Bridge is a gigantic engineering project for both rail and motor vehicle transit between Asia and Europe continents, which connects the Black Sea to the Mediterranean Sea over the Sea of Marmara.

Yavuz Sultan Selim Bridge is not just the tallest suspension bridge of the globe thanks to its height of 322 meters, at the same time, it is the widest of the world with a deck width of 59 meters, and with 1408 meters of main span, it is also the longest bridge of the world having a railway flowing over it.

The European main tower of Yavuz Sultan Selim Bridge has been constructed by Yüce Yapı.

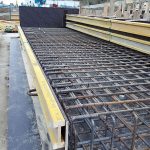

Within the scope of this work continued for 18 months, slipform was used for the first 207 meters of bridge piers, while PERI / ACS (Auto Climbing System) cast-in-place formwork which was assembled at the site was used between the heights 207 m – 304 m. With the use of ACS system having a height of 11 meters in total and a concrete casting height of 4.5 meters, totally 40 climbing sequences, consisted of 20 climbs for each North and South piers, were achieved and concreting was completed at the level of +304.50. For this work, besides 4514 tons rebar installation in total, 18926 m3 concrete casting and 13813 m2 ACS formwork assembly was performed.

Construction of sidewalks to be used by operation and maintenance teams who will support the daily work flow and security on the bridge has been performed by Yüce Yapı.

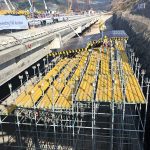

At the first stage of the project which was realized as a two-stage construction; for the reinforced concrete structure of the sidewalk, heavy-duty scaffolds were used at heights suitable for scaffolding, on the other hand for heights not suitable for scaffolding, construction was performed by use of Counter-Weight Form Traveler system. Besides use of 366 tons rebar for construction of European Sidewalk, 7880 m2 formwork assembly and 1800 m3 concrete casting was performed. Totally 6 Counter-Weight Form Travelers were used at different points of this project.

We have performed manufacture and on-site assembly of precast beams necessary for closing top of the main cable chamber.

Yüce Yapı has closed the top of the European Anchor Block main cable chamber with precast beams weighing almost 30 tons. For precast beams which were manufactured at the site, 311 m3 concrete casting, 79 tons rebar installation and 942 m2 formwork assembly was accomplished. After erection of beams, upper deck and concrete filling works were completed.

Within the scope of Anchor Block Transition Slab construction for providing transition from highway to the bridge connection viaduct, Yüce Yapı accomplished manufacture of 487 m2 formwork assembly, 135 tons rebar installation, and 1521 m3 concrete casting.

Retaining walls were constructed in order to protect ground and foundations of the substation building located on a hill at the European Side.

Even though the existence of serious technical difficulties and hardly tolerable risks brought by the restricted work area under completely constructed Side Span, Yüce Yapı succeeded in completing one of the world’s hardest bearing installation.

As Yüce Yapı, we accomplished installation and pre-settings of 12 pieces of Pendulum Bearings (4 pieces of 14350 kg, 4 pieces of 8640 kg, and 4 pieces of 7400 kg) under the side-span. As the manufacture of these bearings, specially designed by MAGEBA, by taking into account project loads was time consuming, elastomeric bearings were used temporarily at the beginning of project. And, permanent bearings were mounted in their place by Yüce Yapı only after completion of side-span superstructure works completely. Therefore, this is also considered as a bearing replacement project.

Since there was no way to use a crane for these permanent bearings, they were brought to the mounting area under Side Span by the help of the steel rail and moving platform; and then they were taken to the very narrow assembly area by sliding them with a Moving Wagon. Afterwards whole installation process including upper and lower pedestal reinforcements, concrete casting by reverse suspended formwork, non-shrink grouting and epoxy injection were carried out by Yüce Yapı.

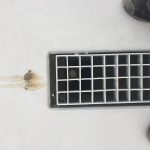

One of the world’s largest expansion joint assemblies for the world’s largest suspension bridge deck has been realized by Yüce Yapı.

Expansion joints manufactured by Maurer Söhne having a total length of 59 meters (Roadway: 17.465 meters X 4 pieces; Railway: 9.80 meters x 2 parts; Sidewalk: 4.08 meters x 4 Pieces; Technical Zone: 2.50 meters x 4 pieces) and an elongation capacity of 1640mm were installed by Yüce Yapı.

During the installation period, as the season was summer, deck elongation within the day was very rapid and extreme due to high temperature difference between the daytime and night. Because expansion joints had been preset at 20οC, fixing of them was requiring a race against time; thus, fixing operation was started just before sunrise when the shortening was highest, and completed within the day by a very coordinated, planned and rapid work. After fixing operation, concreting and assembly were completed. Additionally, welded connections of the multi-part expansion joint were made by Yüce Yapı.

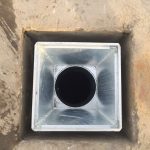

Yüce Yapı has completed manufacture and assembly of steel drainage system consisted of 112 pieces for the full-length of the deck which is 2008 meters, comprised of 1408m Main Span and 600m Side Span, for preventing accumulation of rainwater on the bridge. This project was carried out from end to end by Yüce Yapı including workshop manufactures, on-site assembly, Steel deck and its welded connections.

Yüce Yapı manufactured the platforms for creating a work area and providing a transition between North and South Pylons at levels of +299 and +269 of European and Asian towers, respectively.

The manufacture and assembly of stairs enabling access to the inside of TTB (Tower Top Beam) Lower Panel of European and Asian towers of the Bridge were performed by Yüce Yapı. Since access to this zone was achieved through just one manhole and a narrow Tower Elevator, these stairs were designed and manufactured as multi-element small modules, and then they were carried to their place manually for assembly and welding.

For all maintenance works required for sustainability of Yavuz Sultan Selim Bridge, it is necessary to walk safely on the Main Cable.

Steel structures necessary for assembly of Hand Ropes on the Main Cable have been manufactured by Yüce Yapı.

Manufacturing and installation of all gates on the bridge structures (Main Tower, Side Span, Anchor Block and etc.) have been made by Yüce Yapı. A 60-doors set where 40% was fireproof was completed.

Various steel structures such as Manhole covers, Aviation Supports, Navigation Supports, skirt plates, Pier4 Working Platforms, Lifting frame were manufactured by Yüce Yapı.

Installation of European Side Span formwork panels as well as manufacture of upper deck formwork and scaffolding at Segment 1 were conducted by Yüce Yapı.